Introduction

Our company has been working on process control and automation projects in different segments of industry since 1996. The company went through a major transformation in 2003.

Since the very beginning we put...

More

Our experts

Our engineers have two decades of experience in the area of industrial process automation. They are registered members of the Hungarian Chamber of Engineers and have full license to design building electricity and automation systems.

We also have experts for electric shock protection examinations.

We hire skilled and experienced professional subcontractors for the construction and making tasks. The quality of their work is guaranteed by our partnership that has been successfully operating for many years by now. Our comprehensive liability insurance is also valid for the work of our subcontractors.

More

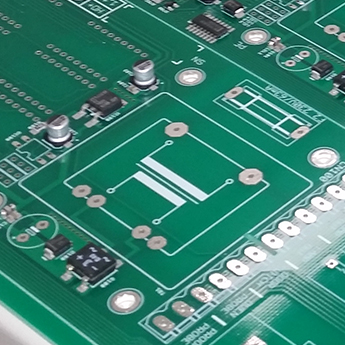

Technical background

Our firm puts ephasize on owning and using the best quality equipment that our projects require.

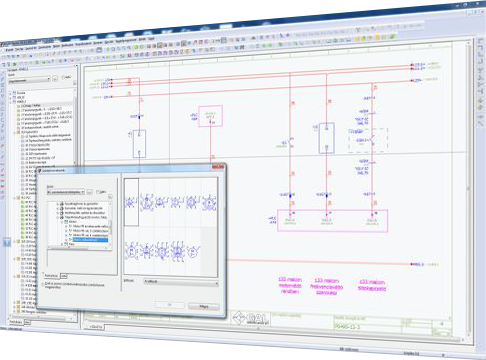

We use legal softwares only. Our electrical designing and documentation work is supported by the latest EPLAN Professional CAD system.

More

Profession

Our engineering activity includes system integration works, electrical engineering, system plan developing and creating logic designs.

Our professional colleagues are registered at the Hungarian Chamber of Engineers. We consider it very important to create high standard comprehensive documentation about the designed systems. Our engineering and documentation work is supported by the latest EPLAN Professional CAD system.

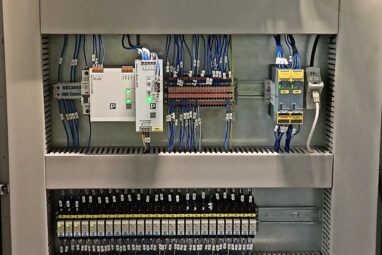

The most important aspect when choosing our equipment is reliability.

We only install certified parts and equipments which are made by well known manufacturers. For control functions we mostly use Siemens products, for protection and switching appliances we use EATON, Schneider and Siemens products and our accessories are mostly made by Weidmüller, WAGO, Rittal, Omron and Datcon. Of course we are also open to cooperate with different suppliers if required.

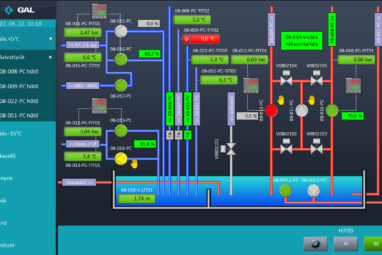

Our program development activity includes creation of control software and applications for PLC based control systems; developing and programming supervisory, control, and data acquisition (SCADA) systems as well as making human-machine interface applications (e.g. for operator panels, PC).

Our professionals rely on their own decennial experience when developing the operation and structural concept, and working out algorithms.

According to the requirements and possibilities we develop modular structures to help further expansions.

We use the latest developing systems (ex.: Siemens Step7 Professional, S7 MicroWin, Teleservice, ProTool/Pro, WinCC, Citect, C++ Builder stb.).

The completed programs go through a detailed and careful pre- and on-site testing. After putting in operation the final software are given to our client including comments in a full form to make repairs and fault diagnosis easier.

Our company constructs process control systems and cabinets from quality parts according to the valid European and national standards, and according to our costumer's requirements. After finishing the installation and cabling works we make and document the needed revisions.

Our partners and subcontractors cost-effective and professional work is guaranteed by our partnership that has been successfully operating for years by now.

Our colleagues have many years of experience in fault diagnosis and recovery of PLC based or other control systems.

We undertake electrical and automation-oriented repair and maintenance works in occasional or contracted construction.

References

2023.,

Sopron

2023.,

Budapest

2022.,

Szerencs

2022.,

Budapest

2022.,

Sopron

2021.,

Győr

2021.,

Győr

2021.,

Sopron

2020.,

Bőcs

2020.,

Sopron

2020.,

Sopron

2020.,

Szerencs

2020.,

Szerencs

2020.,

Győr

2020.,

Diósgyőr

2020.,

Kecskemét

2019.,

Szerencs

2019.,

Szerencs

2019.,

Soron

2019.,

Győr

2019.,

Sopron

2019.,

Sopron

2019.,

Szerencs

2019.,

Sopronhorpács

2017.,

Sopron

2017.,

Sopron

2017.,

Sopron

2017.,

Budapest

2017.,

Sopronhorpács

2016.,

Ózd

2015.,

Turkey

2015.,

Sopron

2015.,

Ózd

2014.,

Szerencs

2014.,

Bükk

2014.,

Szerencs

2014.,

Kecskemét

2014.,

Diósgyőr

2014.,

Szerencs

2014.,

Sopron

2013.,

Turkey

2013.,

Sopron

2013.,

Sopron

2013.,

Szerencs

2012.,

Turkey

2012.,

Szerencs

2012.,

Diósgyőr

2012.,

Sopron

2012.,

Sopron

2012.,

Szerencs

2011.,

Szerencs

2011.,

Szerencs

2011.,

Budapest

2011.,

Diósgyőr

2011.,

Kecskemét

2010.,

Szerencs

2010.,

Szerencs

2010.,

Budapest

2010.,

Sopron

2010 Bőcs

2009.,

Sopron

2009.,

Kecskemét

2009 Kecskemét

2008.,

Budapest

2008.,

Budapest

2008.,

Budapest

2008.,

Budapest

2008.,

Sopron

2008.,

Budapest

2007.,

Szerencs

2007.,

Szerencs

2007.,

Tahitótfalu

2006.,

Budapest

2006.,

Budapest

2006.,

Bőcs

2006.,

Sopron

2006.,

Budapest

2005.,

Tiszavasvári

2005.,

Szerencs

2005.,

Miskolc

2005.,

Mór

2004.,

Budapest

2003.,

Kőrösladány

2004.,

Budapest

2004.,

Szerencs

2004.,

Kisbér

2004.,

Paks

2004.,

Budapest

2004.,

Vasmegyer

2004.,

Budapest

2003.,

Budapest

2003.,

Greece, Rhodes

2003.,

Paks

2002.,

Saudi Arabia

2002.,

Békéscsaba

2002.,

Budapest

2002.,

Budapest

2001.,

Russia

Borsodi Sörgyár Kft.

Contarex Agrotechnika

Cool Technique Kft.

DrinkSystem Kft.

Dunaferr Zrt.

MBE EWB Technológiai Kft.

Gena Trade Kft.

Heineken Hungária Zrt.

Hikev Kft.

ICE Solution Kft.

Infocontrol Hungária Kft.

Inwatech Környezetvédelmi Kft.

Kapu VIV Kft.

Kvalix Automatika Kft.

Micro-Max Kft.

Műszer Automatika Kft.

Nestlé Hungária Kft.

NÍVÓ QUATTRO Kft.

Petz Control Kft.

RATH Hungária Tűzálló Kft.

Rozmaring Szalo Kft.

Siemens Zrt.

Sole-Mizo Zrt.

Tauril Kft.

Xellia Gyógyszervegyészeti Kft.

Photos of our control panels and softwares

Operating control cabinet

Operating control cabinet Control cabinet inside

Control cabinet inside Pharmaceutical plant refrigeration system schematic diagram (TP1200)

Pharmaceutical plant refrigeration system schematic diagram (TP1200) Central control cabinet of an industrial refrigerration system

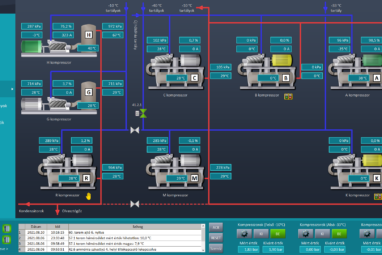

Central control cabinet of an industrial refrigerration system SCADA application of an industrial refrigerration system (WinCC)

SCADA application of an industrial refrigerration system (WinCC) Screw compressor control cabinet

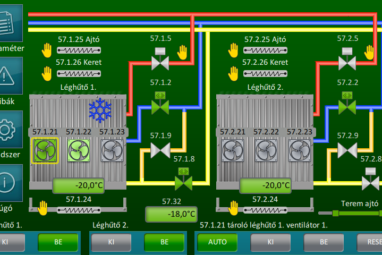

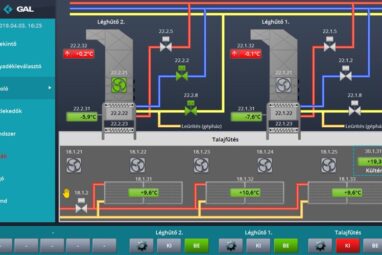

Screw compressor control cabinet HMI application of cold storage chamber control (TP1200)

HMI application of cold storage chamber control (TP1200) Ground heating control cabinet

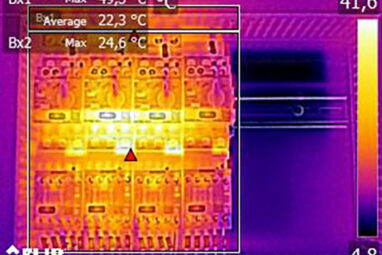

Ground heating control cabinet Thermal camera examination of a control cabinet

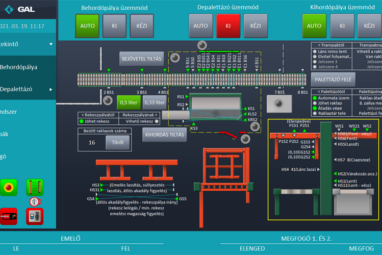

Thermal camera examination of a control cabinet Glass bottle pallet unloading machine schematic digram

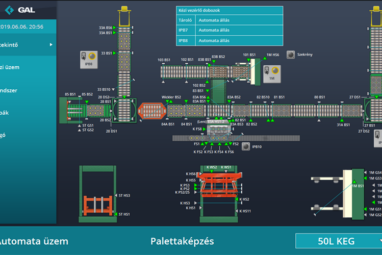

Glass bottle pallet unloading machine schematic digram Keg pallet machine schematic digram

Keg pallet machine schematic digram Protection and distribution of power in the switch cabinet

Protection and distribution of power in the switch cabinet Manufacture of distribution boxes

Manufacture of distribution boxes Ready-mounted control cabinet

Ready-mounted control cabinet Technology control cabinet

Technology control cabinet Dust-proof interface

Dust-proof interface Cooling control (Paks Nuclear Power Plant)

Cooling control (Paks Nuclear Power Plant) Technology Scheme in an Operator Panel

Technology Scheme in an Operator Panel Human-machine connection: analogue signal settings

Human-machine connection: analogue signal settings Overhead conveyor system

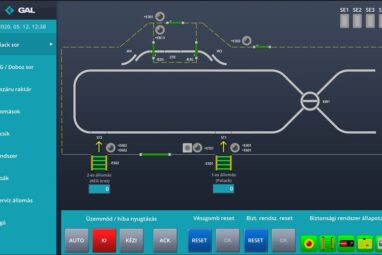

Overhead conveyor system Overhead conveyor system schematic diagram

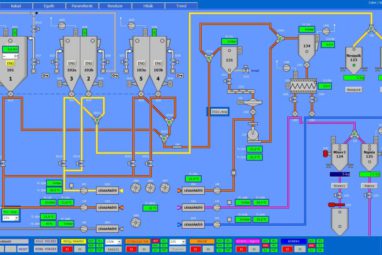

Overhead conveyor system schematic diagram SCADA: Cocoa paste storage and transport system

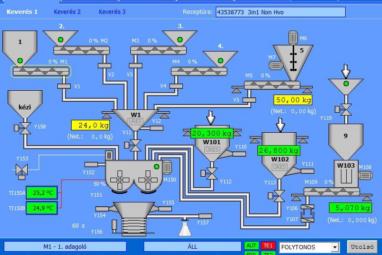

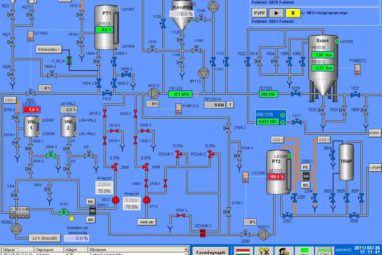

SCADA: Cocoa paste storage and transport system SCADA: schematic diagram of the material supply system

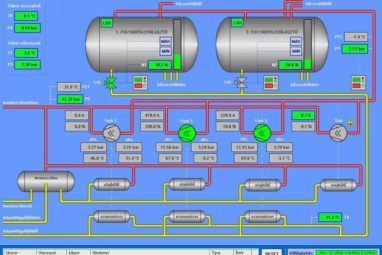

SCADA: schematic diagram of the material supply system SCADA: overview diagram of cooling control

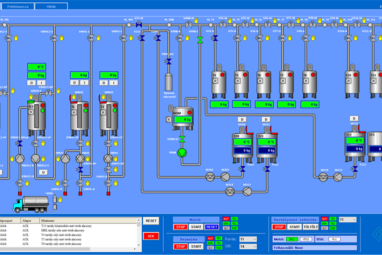

SCADA: overview diagram of cooling control SCADA: food industrial technology

SCADA: food industrial technology Cold storage facility control cabinet

Cold storage facility control cabinet Pallet conveyor control cabinet

Pallet conveyor control cabinet Cold storage facility -20 °C storage schematic diagram

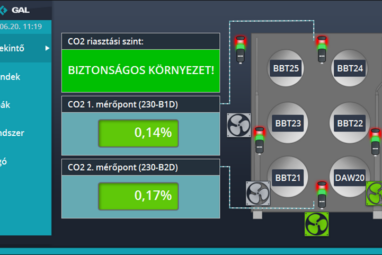

Cold storage facility -20 °C storage schematic diagram Carbon dioxide detecting and ventilation system overview diagram

Carbon dioxide detecting and ventilation system overview diagram

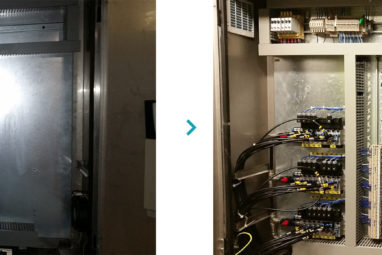

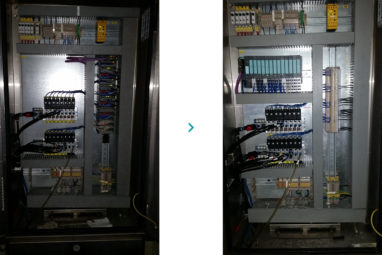

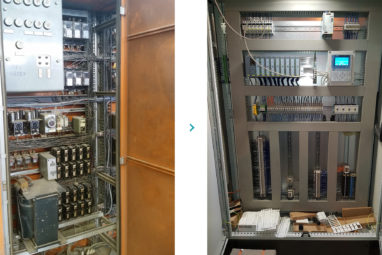

Pictures of renewal works made by our company

Overhead conveyor system trolley control cabinet

Overhead conveyor system trolley control cabinet Raw material Supply line control renewal.

Raw material Supply line control renewal. Development of SCADA application for an industrial refrigerration system

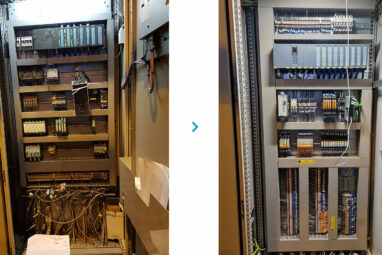

Development of SCADA application for an industrial refrigerration system Renovation of an industrial refrigerration central control system

Renovation of an industrial refrigerration central control system Renovation of cold storage chamber control cabinets

Renovation of cold storage chamber control cabinets KEG charging machine PLC replacement.

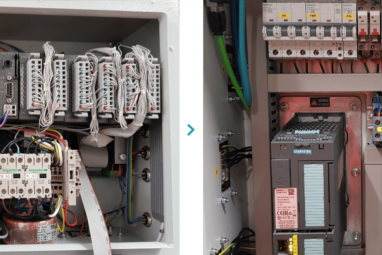

KEG charging machine PLC replacement. KEG track management PLC replacement.

KEG track management PLC replacement. Renovation of controls for bale breaking machines.

Renovation of controls for bale breaking machines. Screw Compressor Control renovations.

Screw Compressor Control renovations. Replacing PLC Replacement Machines.

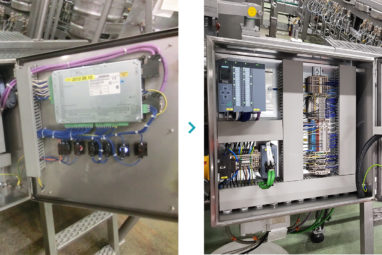

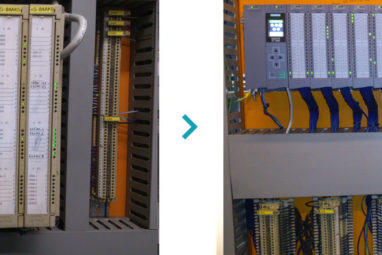

Replacing PLC Replacement Machines. Replacement of VIPA-made remote IO devices to Siemens ET200.

Replacement of VIPA-made remote IO devices to Siemens ET200. Replacement of VIPA-made remote IO devices to Siemens ET200. (2)

Replacement of VIPA-made remote IO devices to Siemens ET200. (2) Cocoa agglomeration production line control renewal.

Cocoa agglomeration production line control renewal. Stapling Machine Control Renovation

Stapling Machine Control Renovation Renovation of controls for bale breaking machines.

Renovation of controls for bale breaking machines. Renovation of brick press control.

Renovation of brick press control.

Products

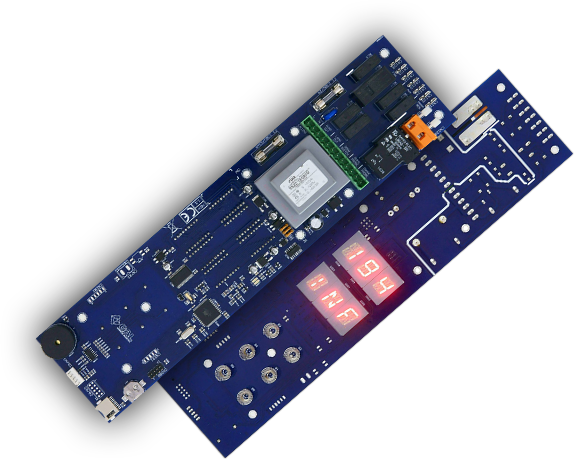

Own-developed and manufactured in series microcontrollers with target controllers with full CE documentation.

There are hundreds of copies in operation of both of these electronics.

KELEMAT PB

proofing cabinet controller

The appliance is used to control proofing cabinets operating in bakeries.

Unitronics Jazz-based device handles proofing programs; has built-in power supply, temperature measurements, power outputs, and liquid level switching.

- Power Supply of Unitronics JAZZ PLC and matching of I / O (8 DO, 1 DI, 3AI)

- DC24V 1.5A Power Supply

- 3 piece of relay output 230V / 6A (fan, compressor, heating)

- 1 piece of 230V / 6A semiconductor output (heating)

- 4 piece of 24VDC semiconductor outputs (fans, valves)

- 2 piece of 4-20mA inputs (temperature, humidity)

- 1 piece of Pt100 / 0-10V converter (-50 ° C ... + 150 ° C)

- 1 piece of Conductive Level Switch Converter

More

HD+

oven controller

The appliance is used to control electric ovens in bakery shops. It handles baking programs, it has temperature measurement inputs, power outputs, wired and wireless communication capability, and memory card slots.

- 1 piece of oven heating control (230V / 20A; Wago pull spring coupling; zero shift switching)

- 1 piece of fan control output with rotational direction change (230V / 1A)

- 1 piece of water pump control output (230V / 1A; disconnectable terminals connection with screws)

- 1 piece of oven light control output (230V / 1A; disconnectable terminals connection with screws)

- 2 piece of aux control outputs (230V / 1A; Faston connector)

- 1 piece of beep signal (piezo buzzer)

- 1 door switch input (NC contact, disconnectable terminals connection with screws)

- 1 Pt1000 oven thermometer input (-20 ° C to + 300 ° C; disconnectable terminals connection with screws)

- 1 Kyt81 Thermometer Input (-20 ° C to +100 ° C; disconnectable terminals connection with screws)

- 1 SSR control output (PID control option, disconnectable terminals connection with screws)

- USB port (parameterization, programming, diagnostics)

- SD card (logging)

- RTC (real-time battery-protected clock)

- Bluetooth interface (optional)

- Alphanumeric LED display with 2x3 characters

- 6 touch-sensitive (QTouch) user interfaces

- 99 program positions (3 baking phases per program: temperature, steam, time, 1 sowing temperature)

- timed switch-on (up to 1 week)

- PID oven temperature control (optionally connected to SSR)

- logging of baking programs on SD card

- internal diagnostic storage

More

Quality assurance

Our firm has been operating under quality control according to EN ISO 9001:2008 standard since January, 2005.

we strive for stable operation, to broaden our customer base, and to better serve our customers' needs.

1. Our main processes

- Our main processes controlled by our Quality Management System:

- Designing, manufacturing, producing and on-site assembling of the Industrial Process Control Systems.

- Maintenance and repair of industrial process control systems

- Distribution of electrical industrial products

2. Customer centered operation

The main source of our profit is customer satisfaction, so

our policies are tailored to customer focus.

- So, according to this:

- We are trying to get acquainted with our existing (and potential) customers' needs for our services.

- We strive to find a practical and cost-effective way to meet customer needs.

- We pay attention to customer demand and we improve our activities based on differences.

3. Contact with other regulations

The Quality Management System is designed to integrate

organically into our other regulations, thus providing

a tight unit for accounting and other systems.

4. Gradual development

Our company wants to be the most recognized in the field for long-term.

To do so, it has established a quality management regime that consists

of step-by-step measurably improved and developed elements. We strive to achieve this.

5. Practical implementation, commitment, recognition

We build up a system that is not just a theory in regulation, but

a rule that determines our everyday practice.

Our management takes the necessary steps for our quality policy to

be known and expects its' employees to identify with it.

G. GDPR

GAL Mérnöki Iroda Kft undertakes to ensure that any data management related to its activities complies with the current requirements.

Our latest Privacy Notice is available at the following link: *link*

C. Certificate

The certification registration number of our firm cerfified by the MartonCert Rendszertanúsító Kft., is: 10253819.

The certificate can be downloaded here: GAL Mérnöki Iroda Kft - 10253819

The certifiate is valid until April 29, 2028.

Contact

Impressum

© Copyright 2025, GAL Mérnöki Iroda Kft., Budapest, Hungary

All rights reserved. Text, pictures, graphics and videos and their arrangement on these sites are copyrighted. These content are forbidden to use, copy, distribute or change for business or other purposes.

The site is not using cookies!

GAL Mérnöki Iroda Kft.

GAL Engineering Ltd.

Tahi u. 24.

H-1139 Budapest

Managing director: Mr. Artúr Kiss

Technical manager: Mr. Krisztián Tapuska

EU tax No. : HU13142665

Trade register No. : Cg. 01-09-720827

Telephone/fax : (+36) (1) 320 8183

E-mail: iroda@gal-mi.hu

Graphic design and programming: GFX Design Kft.